New Concept Battery

1. Flywheel battery

As we all know, when the flywheel rotates at a certain angular velocity, it has a certain amount of kinetic energy. The flywheel battery converts its kinetic energy into electrical energy. A high-tech flywheel stores electrical energy, much like a standard battery.

Working principle: The wheel energy storage battery system includes three core parts: a flywheel, motor, generator, and power electronic conversion device. The power electronic conversion device inputs electrical energy from the outside to drive the motor to rotate, the motor drives the flywheel to rotate, and the flywheel stores kinetic energy (mechanical energy). It becomes the electric energy of various frequencies and voltage levels required by the load to meet different needs. Since the input and output are independent of each other, the motor and generator are often implemented with one motor in the design, and the input and output converters are combined into one so that the size and weight of the system can be greatly reduced.

Application:

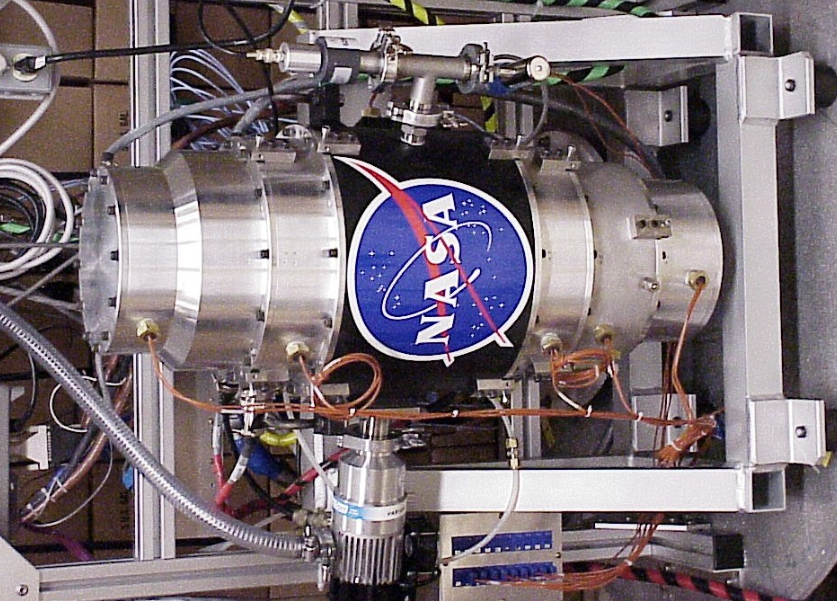

(1) SPACE. Including satellites, spaceships, and space stations, a flywheel battery can provide twice the power of a rv 12v lithium ion battery of the same weight, and the use time of the same load is 3 to 10 times that of a chemical battery. At the same time, because its rotational speed is measurable and controllable, the amount of electrical energy can be checked at any time. NASA has installed 48 flywheel batteries on the space station, which can provide more than 150KW of power. It is estimated to save about $2 million compared to chemical batteries.

(2) Transportation. Including trains and automobiles, this kind of vehicle adopts a hybrid drive of an internal combustion engine and an electric motor. The flywheel battery charges quickly and discharges completely, making it very suitable for use in vehicles powered by hybrid energy. During normal driving and braking, the flywheel battery is charged. The flywheel battery provides power to the vehicle when accelerating or climbing to ensure that the vehicle runs at a stable and optimal speed, reducing fuel consumption. Consumption, air and noise pollution, maintenance of the engine, and prolonging the engine’s life. TEXAS University in the United States has developed a flywheel battery for automobiles. The battery can provide 150KW·h of energy when the vehicle needs it and accelerate a fully loaded vehicle to 100Km/h. In terms of trains, Germany’s Siemens has developed a flywheel battery with a length of 1.5m and a width of 0.75m, which can provide 3MW of power and, at the same time, can store 30% of the braking energy.

(3) Uninterruptible power supply. The flywheel battery can provide a highly reliable and stable power supply, which can provide power from a few seconds to a few minutes, which is enough time to ensure the power switch in the factory. German GmbH has manufactured a UPS that uses flywheel batteries, which can provide or absorb 5MW of electrical energy within 5s.

(4) Military vehicles. The U.S. Department of Defense predicts that future combat vehicles will require extensive electrical energy in communications, weapons, and protection systems. Due to their rapid charge and discharge, independent and stable energy output, and lightweight, flywheel batteries can make the vehicle work in an optimal state. The advantages of reducing the noise of the vehicle (very important in combat) and improving the vehicle’s acceleration performance have become the primary consideration of the energy storage device for the U.S. military.

2. Gel battery

The colloidal lead-acid battery is an improvement of the ordinary lead-acid battery with liquid electrolyte. The sulfuric acid electrolyte is replaced by the colloidal electrolyte, which is improved compared with ordinary batteries in terms of safety, storage capacity, discharge performance, and service life. The colloidal electrolyte is to solidify the sulfuric acid electrolyte into a colloidal substance by adding a gelling agent to the electrolyte. Usually, colloidal stabilizers and compatibilizers are added to the colloidal electrolyte. Agent for easy colloid filling.

Working principle: The domestic colloidal lead-acid battery used for electric bicycles is poured into the AGM separator by vacuum infusion, and the silica gel and sulfuric acid solution are poured into the positive and negative plates of the battery. The colloidal lead-acid battery cannot carry out oxygen circulation in the early stage of use because the colloid surrounds the positive and negative plates. The oxygen generated on the positive plate cannot diffuse to the negative plate and cannot achieve lead reduction with the active material on the negative plate. It can only be discharged by the exhaust valve, which is consistent with the flooded battery.

After the colloidal lead-acid battery is used, the colloid begins to crack and shrink, resulting in cracks, and oxygen goes directly to the negative plate through the cracks for oxygen circulation. The exhaust valve is no longer opened frequently, and the colloidal lead-acid battery is close to sealing, with little water loss. Therefore, the main failure of electric bicycle batteries is the water loss mechanism, and colloidal lead-acid batteries can achieve very good results. The colloidal electrolyte is to solidify the sulfuric acid electrolyte into a colloidal substance by adding a gelling agent to the electrolyte. Usually, colloidal stabilizers and compatibilizers are added to the colloidal electrolyte. Agent for easy colloid filling.

Application:

- Communication system: switches, microwave stations, mobile base stations, data centers, radio, and broadcasting stations.

- Power plants and power transmission and transformation systems.

- Wind and solar powered generator systems.

- Signal system and emergency lighting system.

- EPS and UPS systems.

3. Micro nuclear battery

A penny-sized nuclear battery refers to a “nuclear battery” that is small in size, only the thickness of a penny coin, has strong power and is safe to use. It can be used for mobile phone charging. You can let your mobile phone be used for 5000 years without charging.

How it works: Principle has developed an ultra-miniature power device by utilizing micro- and nano-scale systems, which, through the decay of radioactive substances, releases charged particles to obtain a continuous current.

Applications: Aviation, marine equipment, pacemakers, and artificial hearts.

4. Vanadium battery

The full name of the vanadium battery is all vanadium redox flow battery (VRB).

How it works: Vanadium batteries convert the energy stored in an electrolyte into electricity by exchanging electrons between two types of vanadium ions, separated by a membrane. The electrolyte is a mixture of sulfuric acid and vanadium, the same acid as a traditional lead-acid battery. Since this electrochemical reaction is reversible, VRB batteries can be both charged and discharged. With the change in the concentration of the two vanadium ions during charging and discharging, electrical and chemical energy is converted into each other. VRB batteries consist of two electrolyte cells and layers of battery cells. The electrolyte cell is used to hold two different electrolytes. Each battery cell comprises two “half cells” sandwiching a separator and electrodes for collecting current. Two different “half cells” hold vanadium electrolytes in different ionic forms. Each electrolyte cell is equipped with a pump to deliver electrolytes for each “half-cell” in a closed pipeline. When the charged electrolyte flows through the battery cells layer by layer, electrons flow to the external circuit, which is the discharge process. When electrons are transported from the outside to the inside of the battery, the reverse process happens: to charge the electrolyte in the battery cells, which are then pumped back to the electrolyte cell. In VRB, the electrolyte flows between a plurality of battery cells, and the voltage is formed by connecting the voltage of each cell in series. The nominal voltage is 1.2V. The current density is determined by the surface area of the current collector within the cell. Still, the current supply depends on the flow of electrolytes between the cells, not the cell layers themselves.

Application: It can be used as a backup power supply for buildings, airports, and program-controlled exchange stations; A 12 volt battery can be used as a supporting energy storage device for clean power generation systems such as solar energy; it can provide electricity for submarines, ocean-going ships, and power grid peak regulation.

5. Proton exchange membrane fuel cell

A proton exchange membrane fuel cell (PEMFC for short) is a fuel cell equivalent to the “inverse” device of water electrolysis in principle. The single cell consists of an anode, a cathode, and a proton exchange membrane. The anode is where the hydrogen fuel is oxidized, and the cathode is where the oxidant is reduced. Both poles contain catalysts that accelerate the electrochemical reaction of the electrodes, and the proton exchange membrane is used as the electrolyte.

How it works: The working process of a fuel cell is the reverse process of water electrolysis. PEMFC technology is currently the most mature technology in the world that can combine hydrogen and oxygen in the air to form clean water and release electricity:

- Hydrogen reaches the anode through pipes or gas guide plates. Under the action of an anode catalyst, hydrogen The molecule dissociates into positively charged hydrogen ions (i.e., protons) and releases negatively charged electrons.

- Hydrogen ions pass through the electrolyte (proton exchange membrane) to the cathode; electrons pass through the external circuit. The electrons form a current in an external circuit, and power can be output to the load through appropriate connections.

- At the other end of the battery, oxygen (or air) reaches the cathode through pipes or gas guide plates; under the action of the cathode catalyst, oxygen reacts with hydrogen ions and electrons to form water.

There are many kinds of fuel cells, and the difference between the various fuel cells is the electrolyte used. The proton exchange membrane fuel cell uses the proton exchange membrane as the electrolyte, which is characterized by low operating temperature (about 70-800C) and fast start-up speed and is especially suitable for use as a power battery. The chemical reaction temperature in the battery generally does not exceed 80 degrees, so it is called “cold combustion.”

Application:

It is used as a portable power supply(such as portable solar panels or portable power station) , small mobile power supply, vehicle power supply, backup power supply, uninterruptible power supply, etc. It is suitable for military, communications, computers, geology, microwave stations, meteorological observation stations, financial markets, hospitals, and entertainment places. , to meet the needs of field power supply, emergency power supply, high reliability, and high stability power supply. The minimum power of PEMFC power supply is only a few watts, such as mobile phone batteries. According to reports, the PEMFC cell phone battery has a continuous standby time of up to 1000 hours and a talk time of up to 100 hours on a single refill (Motorola). The power range of PEMFC power supplies suitable for portable electronic devices such as portable computers is roughly tens of watts to hundreds of watts (Toshiba). The power of the military backpack communication power supply is on the order of hundreds of watts. The onboard PEMFC power supply for satellite communication vehicles is generally several kilowatts.

It can be used as power for vehicles such as mopeds, motorcycles, cars, trains, ships, etc., to meet environmental protection requirements for vehicle and ship emissions. PEMFC has a low operating temperature, fast start-up speed, and high power density (small size), so it is very suitable for new vehicle power generation. This is an application with great potential. Since automobiles are the primary cause of energy consumption and environmental pollution, the world’s major automobile groups are competing to invest huge amounts of money in the research and development of electric vehicles and alternative fuel vehicles. Judging from the current development situation, PEMFC is the most mature electric vehicle power source, and the industry recognizes PEMFC electric vehicles as the future development direction of electric vehicles. Fuel cells will become the third generation of power systems after steam engines and internal combustion engines. PEMFC can achieve zero or low emissions; its output power density is much higher than current gasoline engines, up to 1.4KW/kg or 1.6KW/L. The power range of PEMFC systems used as power for electric bicycles, mopeds, and motorcycles are 300-500W, 500W-2KW, and 2-10KW, respectively. The power of the PEMFC power system for light vehicles such as tour buses, urban engineering vehicles, and cars is generally 10-60KW. The power of the bus needs 100-175KW. PEMFC is used as a power source for submarines, compared with Stirling engines and closed-cycle diesel engines, has the advantages of high efficiency, low noise, and low infrared radiation, which is of great significance for improving the concealment, flexibility, and combat capability of submarines. The navies of the United States, Canada, Germany, Australia, and other countries have been equipped with submarines powered by PEMFC, which can continuously dive underwater for a month.

It can be used as a decentralized power station. The PEMFC power station can be shared with the grid power supply system and is mainly used for peak shaving; it can also be used as a decentralized main power supply source for independent power supply, suitable for use as a power station in islands, mountainous areas, remote areas or newly developed areas.

Compared with the centralized power supply method, the decentralized power supply method has many advantages:

- It can save the power grid line and the power distribution dispatching control system;

- It is beneficial to the combined heat and power supply (because the PEMFC power station has no noise, it can be installed nearby, and the PEMFC power generation produces The heat that can enter the heating system), which can make the total fuel utilization rate as high as 80%;

- It is less affected by wars and natural disasters; Infrastructure such as a gas supply system provides fuel for PEMFC, and a recycling system can be formed through biological hydrogen production and solar electrolysis hydrogen production (this recycling system is especially suitable for the vast rural areas and remote areas), which makes the system construction cost and operation. Costs are greatly reduced. Therefore, the economy and environmental protection of the PEMFC power station are very good. It is generally believed that the development of decentralized power stations will be a trend with the popularization and application of fuel cells.